I made my own gear yesterday!! I'm so proud of it I could just burst.

A little background - I'm building on orrery (model of the solar system) for the astronomy department of a college in San Mateo, CA. We've built similar things, but of course, every new project requires new skills and stuff that we've never done before. For this piece, called Celestial Gears, it is going to be motorized with a computer driving the planets with correctly timed orbits. The whole piece is 6 feet in diameter.

I already have the computer program written to drive the planets, and have the motors lined up that hook to the computer. The planets are on a central shaft that runs down the middle of the decorative rocket ship. Each planet arm is attached to a tube, and the tube goes down into the table where all the mechanisms are.

Now, to connect the tubes to the motors to get the planets to spin, there needs to be a large gear on the tube that connects to a small gear on the motor. The teeth interlock so when the motor spins, its little gear pushes the big gear and the tube rotates which means the planet moves.

I have been searching for appropriate gears for a loooooong time. I can find little ones for clocks and such, but these need to be up to 18 inches in diameter. The only ones I could find like that were upwards of $400 each!! Yeow!! If you've done your math, you'll note that I need two gears for each of 8 planet arms. That's 16 gears! At $400 a pop??? No way!!!

So, like most everything else we do here, I thought "I'll just make my own! How hard could it be??"

First I had to learn all about the geometry and mathematics of gearing. I won't go into all that here. Once I got all that learned, I knew the size of each gear needed and the number of teeth. Now to figure out how to make it using the woodworking and art tools that I have. After a lot of screwing around, and misshapen gear type objects, I finally settled on a method using a drill press, radial arm saw and router.

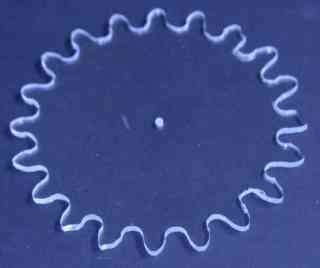

I created the guide pattern in photoshop and then transferred it to my vinyl cutter (a cute little Cricut machine that I just love!), cut out the pattern and went to work. An hour later, I had my first little gear! With the right number of teeth and everything!!! I was so proud!!! I used thin Plexiglass for the sample, which breaks easier, so this one isn't perfect - it has some oogedies and a few cracked off teeth, but the real ones now out of the thicker polycarbonate should be just perfect. So be kind. I know it has flaws, but for a first real gear, it's really quite good, I think! And I really need a pep club to continue to push me. It's really hard making this new thing in my little cone of silence up here.

So here it is: It's 4 inches in diameter. The teeth are about a quarter inch across. Please Please Please comment (but be kind...)

4 Inch Plexiglass Gear

Thank you for reading all this and supporting me.

Peace,

Joy

May 11th, 2009 at 1:03 pm

I can't imaging how difficult this was. I know that when drawing things like stained glass windows with multiple points on the interior, getting everything aligned so that all the arms meet is next to impossible. --Then having to cut it out??

Great job!!

May 11th, 2009 at 3:09 pm

WOW! I am very impressed by what you accomplished due to all that is involved. I completely understand the "how hard could it be" attitude that tends to head me toward the rapids as well but how else do we learn bigger and better things.

Great job.

Robin

May 11th, 2009 at 4:09 pm

You are incredible! Seemingly limitless talent. Gotta love a lady with a radial arm saw and router and knows how to use them. You continue to amaze.

May 11th, 2009 at 5:33 pm

Thank you for the great comments and support!!! It helps me out so very very much. It was very complicated to figure out, but so cool when I cut it and it actually worked!!! Now I just have to figure the works for a 2", 16" and 18", and then cut four of each.

May 11th, 2009 at 5:38 pm

It's a beautiful gear. I make kinetic sculptures too, but the mechanical end of it eludes me. Mine are not motorized but I often think about the mystery of gears and bearings and such. Congrats!

May 11th, 2009 at 9:25 pm

Joy, your work is so versatile. I've had to make gears and tiny little pieces that go into sets and miniatures. I know how difficult they can be.... to get the measurements just right.

You rock.

January 16th, 2011 at 9:25 pm

scalping cutter used for milling of plain surfaces of ferrous as well as non- ferrous metals